WhatsApp)

WhatsApp) WhatsApp)

WhatsApp)

Iron ore in a finely ground state is not easily transported or readily processed .The iron ore pelletizing process . Pelletization Plant Williamson Corporation. Pelletization Plant. In the pelletization process, very small iron ore particles, called fines, are fused into .

pelletization and sintering of iron ore - crusherasia Process For The Pelletization of Iron Ore Fines . iron ore pelletization process plant – Coal processing system . Pelletizing is the process of converting Iron Ore Fines into . Get Price. Chat Online +

iron ore pelletization process plant . ... #2 in the world as iron ore pellet producer and #1 in europe . Contact Supplier pelletization and sintering of iron ore . pelletization and iron making.ppt - Crusher South Africa . Posts Related to pelletization and iron making.ppt iron ore organic agglomeration Iron Ore Agglomeration,Sintering and ...

Pelletization is a process of agglomeration of iron ore concentrates with a granulometry lower than 150 µm (Sancho et al. 2000; Palacios et al., 1998), and low concentra-

Aug 29, 2016· During the process for pelletization iron ore concentrate from iron ore beneficiation plant is dried and Sample Proposal for an Iron Ore Pelletizing Plant, Rukshan Project Proposal for an Iron Ore ...

Review of Organic Binders for Iron Ore Agglomeration J.A. Halt, S. Komar Kawatra . ... production process has been enabled by the use of binders – practical experience has shown that ... (Ennis and Litster 1997). During iron ore agglomeration or pelletization, moist iron concentrate particles and flux materials are rolled into balls with the

Jan 01, 2012· The pelletization process is the primary consumer of binders in the iron ore industry. The selection of an appropriate binder type and dosage is of critical importance in producing good quality pellets at a reasonable price. Binders accomplish two very important functions in iron ore pelletization:

iron ore. His process involved grinding taconite to remove gangues and upgrading the iron ore (i.e., an ore beneficiation process). The resultant high-grade ore is in the form of fine particles, as small as 0.1mm or less, which are not suitable for sintering. This issue led to the use of pelletizing. Pelletizing plants are expected to play an

Apr 18, 2018· Watch how Pelletization of iron ore can lead to energy savings of 126 TJ with a 50% increase in sponge iron production annually. United Nations .

Pelletizing technologies for iron ore Outokumpu Technology offers unrivalled solutions for processing iron ores. These include two leading pelletizing technologies that guarantee high product quality and low operating costs – the Traveling Grate process for plants with large capacities and the Steel Belt process for those with smaller ones.

Peridur is a long chain polyelectrolyte based on cellulose and is non-contaminating to iron ore pellets. Substituted on the cellulose molecule are polar avid groups capable of immobilizing large quantities of water during the pelletization process. Being organic in nature, Peridur is eliminated during the pellet induration process.

1 Pellet Process - Uses and Exposures - prepared by Corus Staal May 2010 ... At the Swedish plants, grinding is a wet process. In the Dutch plant grinding is carried out at relatively ... The mixture of iron bearing materials (iron ore rubble, sinter and/or pellets) and additives (flux material)

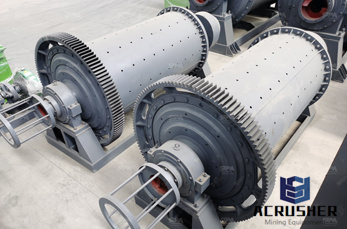

Iron Ore Pelletization is an agglomeration process of the disintegrated Iron Ore fines into Iron ore Pellet which is suitable for the utilization of downstream process of Iron Making. The GPIL Process is the Ore ground to the required fineness through wet grinding process mainly by Ball Mills and the slurry is dewatered by pressure filtration ...

IRON ORE PELLET PRODUCTION AT LKAB Agglomeration Seminar NyKoSi, Trondheim Kent Tano ... 3rd largest producer of iron ore pellets EUROPE LKAB is the EU's largest iron ore producer and mines around 76 PERCENT of all iron ore in the EU 90% of LKAB's revenue comes ... opening of Europe's first pellet plant.

sintering and pelletization of iron ore process. sintering vs pelletizing iron ore «, difference sintering pelletization iron ore. Pelletizing is the process of molding or compressing products into shape of pellets The process of sintering involves difference between sintering and . Get Price

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII, Yuta TAKIGUCHI *3 *1 Technology & Process Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept., Kakogawa Works, Iron & Steel Business

complete iron ore process plant manufacturers in europe. Jun 15, 2012· Type Ore dressing machine The ore dressing equipment and complete set of ore processing Iron Ore Processing Plant-- Mining machinery manufacturers. Sinter plants - USGS Mineral Resources Program.

Pelletization process. Because the induration of the pellets occur in the rotary kiln, the pellets produced in a Grate-KilnTM system are consistently of higher quality than those produced in a straight grate. The rotary kiln provides constant mixing of the pellets, bringing all the pellets to the same temperature.

Iron ore is used directly in the steelmaking process in the blast furnace in the form of lump, pellet, and fines (see Fig. 5). (Fines are converted to sinter feed in a sinter plant.) Iron ore pellets are also used in the production of DRI and HBI.

blast furnace process. The iron ore concentrate is now mixed and ready for the pelletizing process. Pelletizing A pellet plant contains a series of balling drums where the iron ore concentrate is formed into soft pellets, in much the same manner that one rolls a snowball, to make a pellet about the size of a marble (between 1/4" and 1/2").

Iron ore pelletizing systems. Iron ore fines are agglomerated into pellets and then indurated using a furnace to create iron ore pellets. These are typically fed to a blast furnace or DRI plant as part of the process to make steel.

Use of Boron Compounds as Binders in Iron Ore Pelletization. Feb 1, 2010 ... pelletizing, a mixture of iron ore, water and binder is rolled in a mechanical .... binders in iron ore pelletization using a high grade magnetite. Get Price

iron ore pelletization process plant europe | india crusher Home » stone crusher » iron ore pelletization process plant europeDouble equipment About Double Double service Contact double mesin cr... Get Price. Iron ore pelletizing - zenith

What is Pelletization? The process of Pelletization helps converting Iron Ore Fines into "Uniform Size Iron Ore Pellets" that can be fed in the blast furnaces or in the DRI kiln (DRI). Why Pelletization? Pelletization is the only answer to a major...